Properties

Application

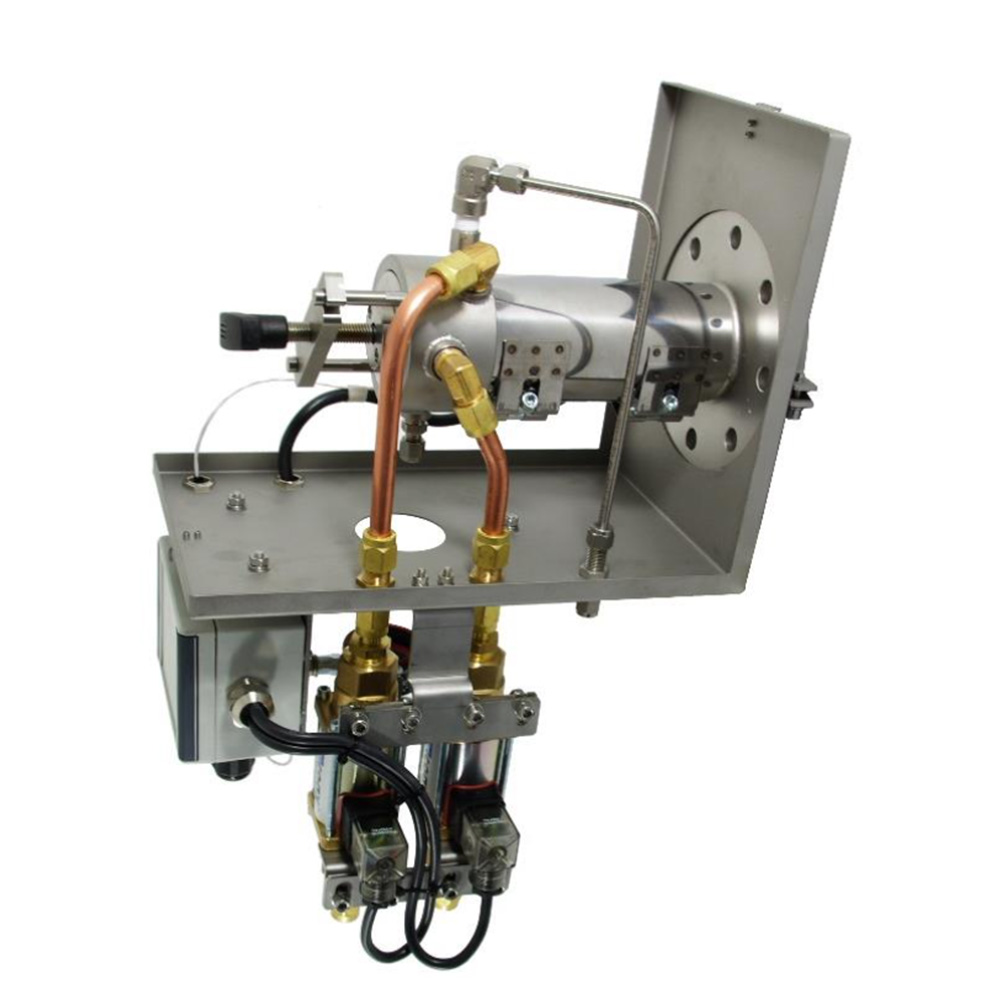

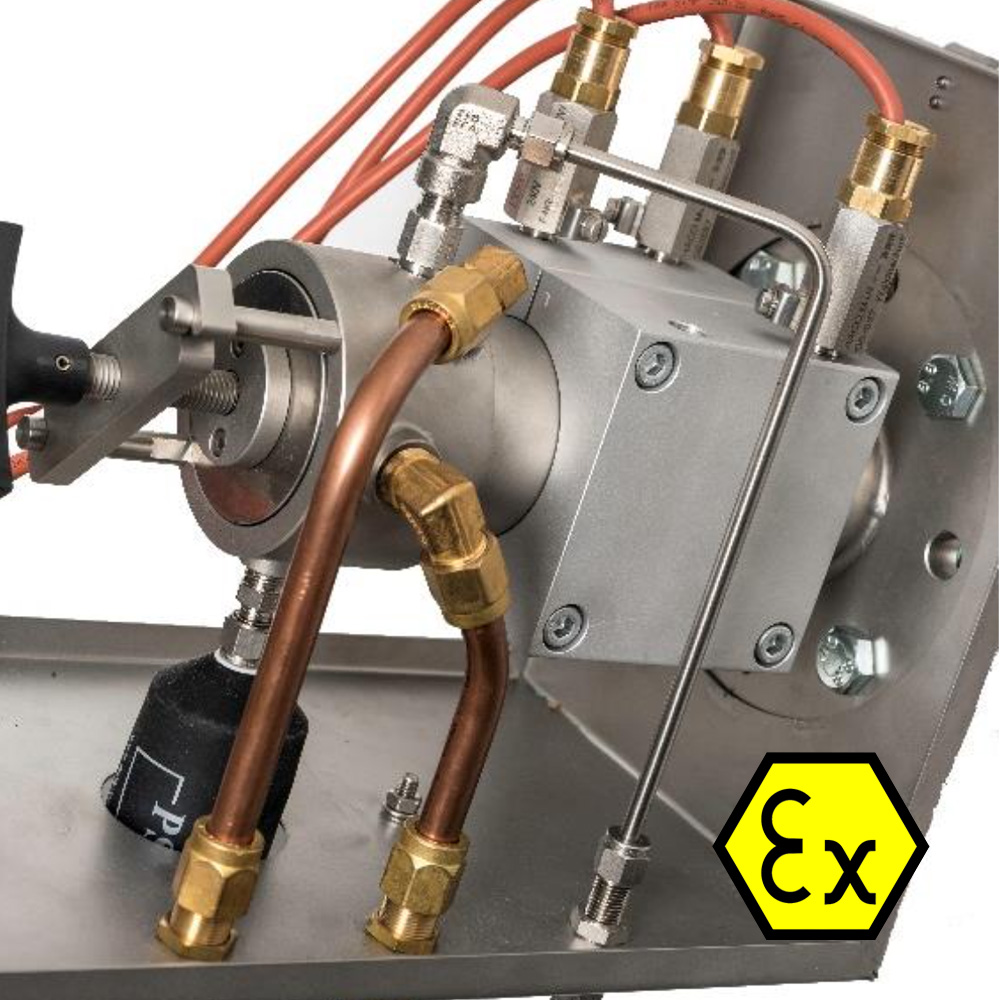

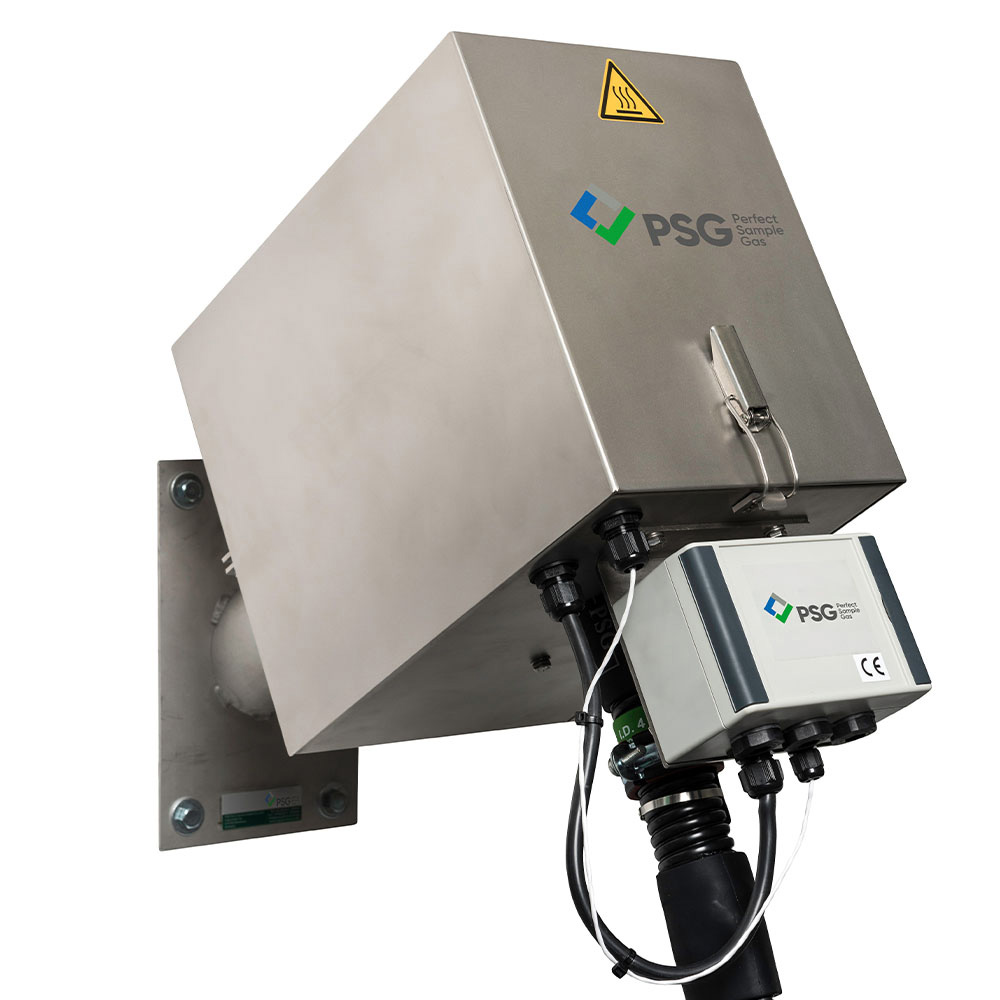

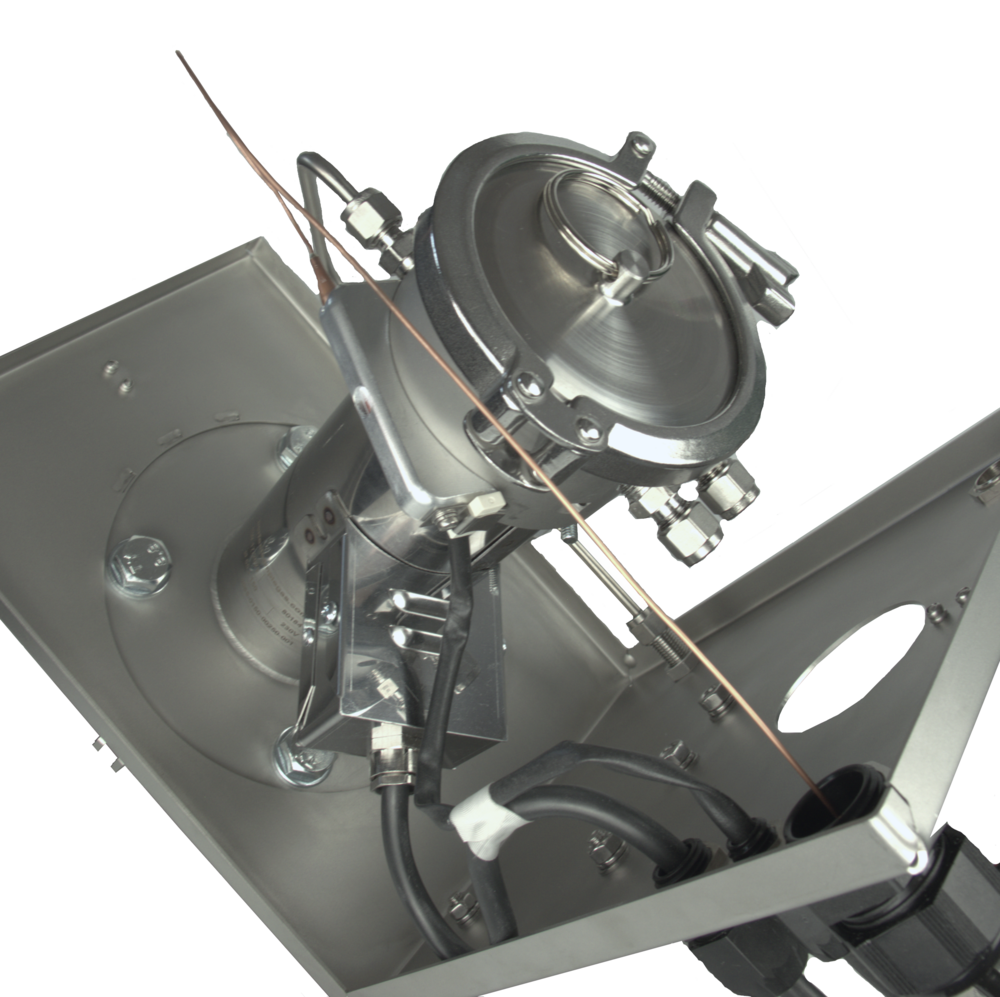

The heated gas sampling probes series PSG Process Probe ATEX 150 are used for continuous extractive gas analysis. They enable trouble-free representative sampling of hot predominantly dust and water vapour loaded gases. Typical applications are measurements and monitoring in explosive plant components.

Technology

The intelligent design with optimum gas guidance enables the filtration of sample gas at the outer filtration surface of 212cm2, allowing service periods of up to 2 years (depending on the dust concentration). If it is necessary to change the filter, the arrowed corkscrew mechanism allows this to be done quickly and conveniently in just a few steps without tools and without disassembling the connected heated sample gas line. The full-surface tight-fitting aluminium heating element with one self-regulating heating cartridge ensures homogeneous heating of the entire PSG Process Probe ATEX 150 to 150°C even at the lowest ambient temperatures.

Functions

Due to the largest filtration surface dust will always be separated reliably in the PSG Process Probe ATEX 150. The heating concept prevents water vapour condensation in order to reliably prevent blocking of the filter. For elevated dust concentrations of up to 40g/m3 resp. 280g/m3 the PSG Process Probe ATEX 150 can be equipped with an ultimate effective single or dual stage back purging with tubing of 12mm outer diameter. In this way filter chamber (single stage) as well as filter element are back purged thoroughly and low-maintenance operation is ensured.