Properties

Application

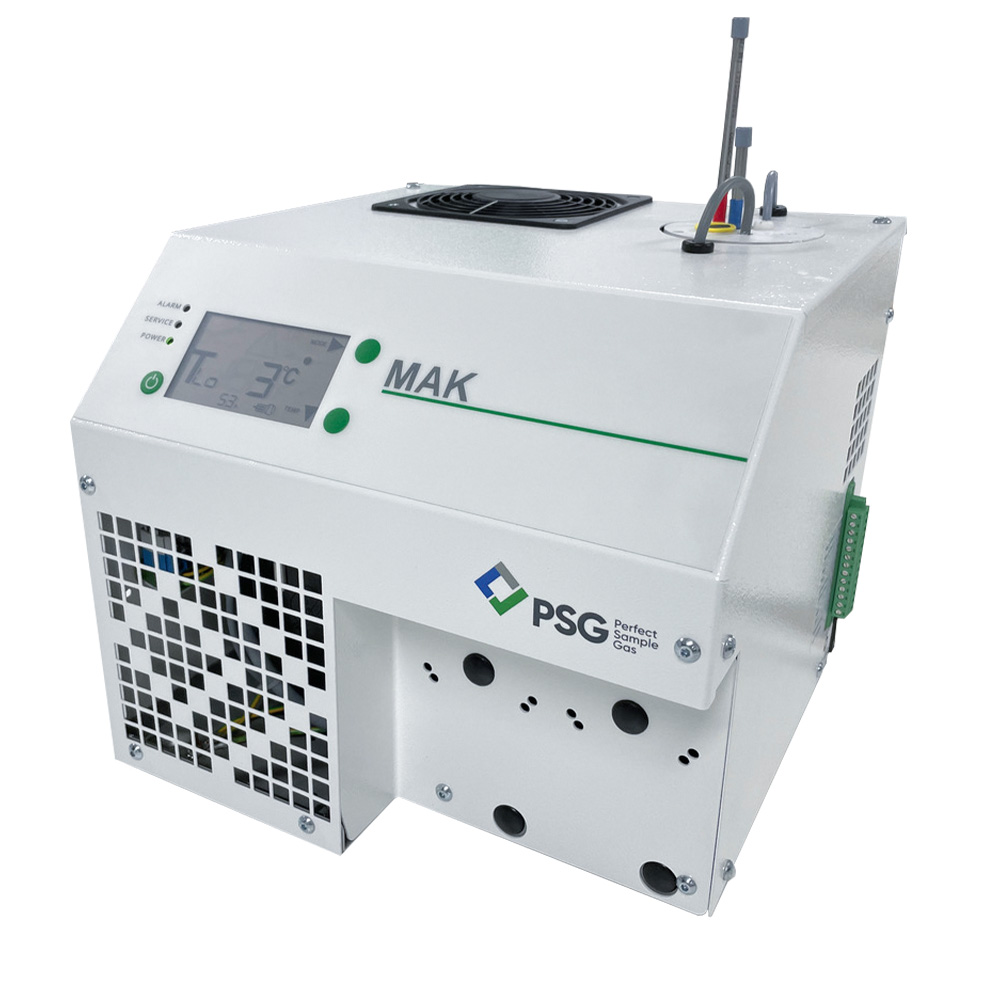

The compact high performance and low maintenance compressor coolers series PSG Process are used for continuous extractive gas analysis. They serve primarily for exact constant lowering of the sample gas dew point and thus for drying of the humid sample gas flow. In this way water vapour cross sensitivities and volumetric errors are minimized and damages of the sensible analyzer are avoided. The high-performance heat exchanger system in the PSG Process series has been specially developed to dry even high gas flow rates precisely, thus promoting rapid transport of the sample to the analyzer. An optional condensate drain is used for condensate removal, which can also be configured in an oxygen-clean version on request

Technology

The precise proportional temperature control in combination with the long-lasting hot-gas bypass system and the innovative corrosion resistant heat exchangers achieves low extremely constant dew points. Also load fluctuations and high thermal stress is compensated reliably. The mono or dual heat exchanger with one or two gas paths is built in a solid aluminum cylinder which guarantees an optimal energy exchange between sample gas and cooling medium. In addition, the aluminum cylinder is an effective cold storage that supports the compensation of unfavorable operating conditions. The MAK Process C is equipped with an exchangeable heat exchanger which allows an easy replacement without dismantling the device.

Functions

The MAK Process C compressor cooler operates with the FCK-free refrigerant R134a. Stainless steel is used as the heat exchanger material. The built-in solenoid valve can quickly and reliably compensate for large load changes. The simultaneously used superheated steam bypass valve achieves more constant sample gas temperatures. The sample gas cooler is equipped with a digital display for checking the sample gas temperature and with a potential-free fault signal contact.