Properties

Application

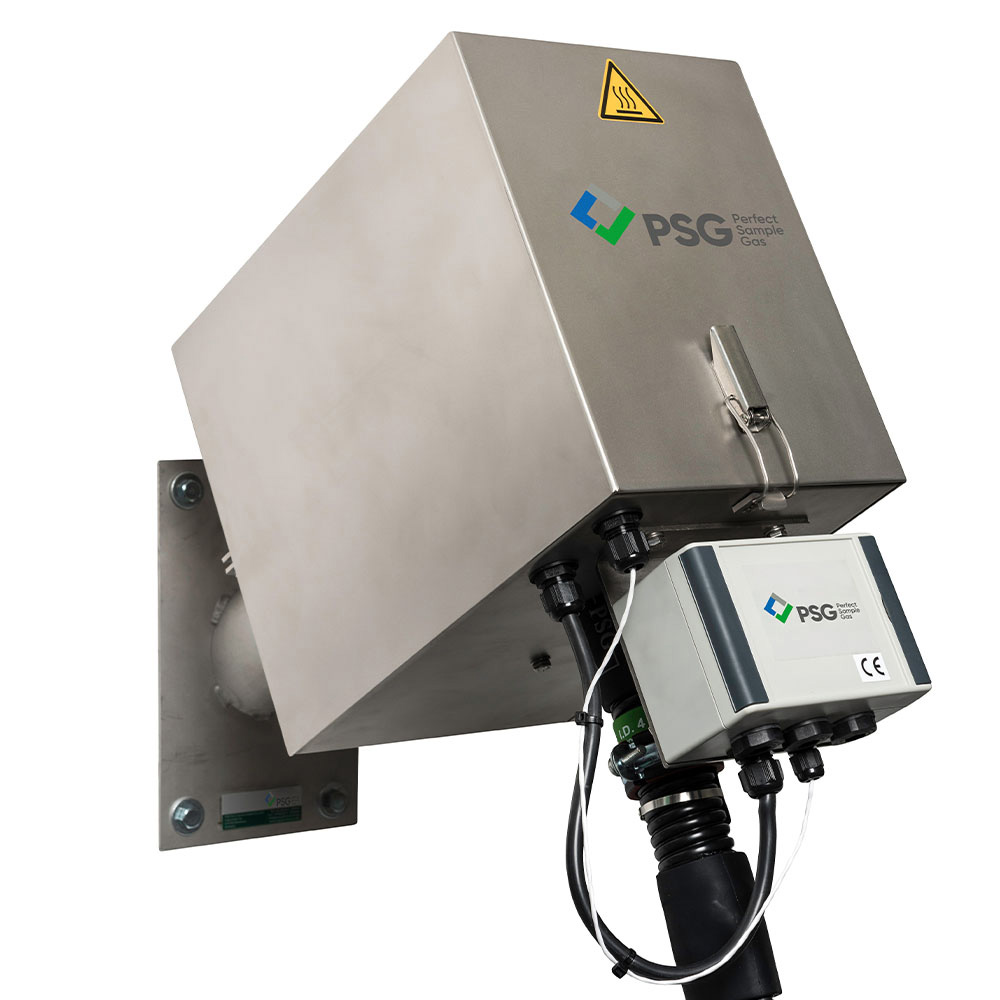

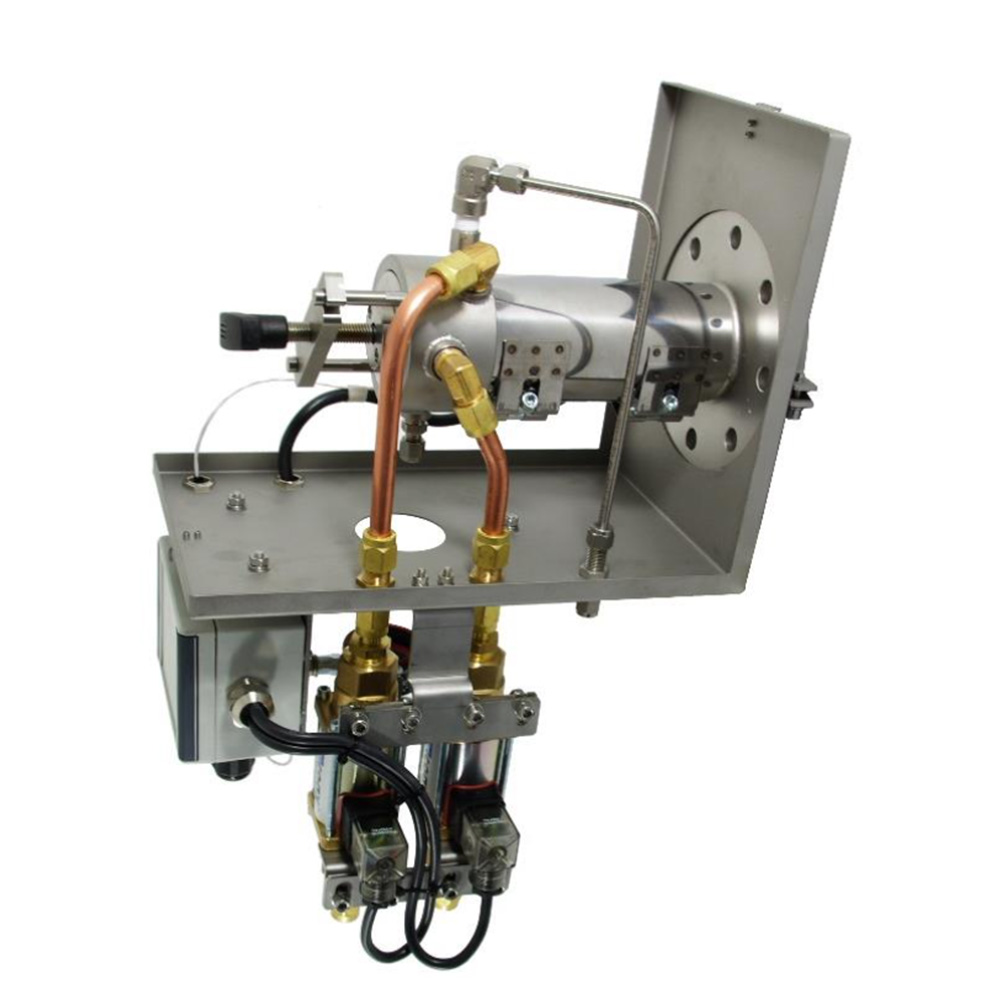

The heated gas sampling probes series PSG Plus Probe Double Back Purge are used for continuous extractive gas analysis. They enable trouble-free representative sampling of hot highly dust and water vapour loaded gases. Typical applications are e.g. process measurements in the cement industry.

Technology

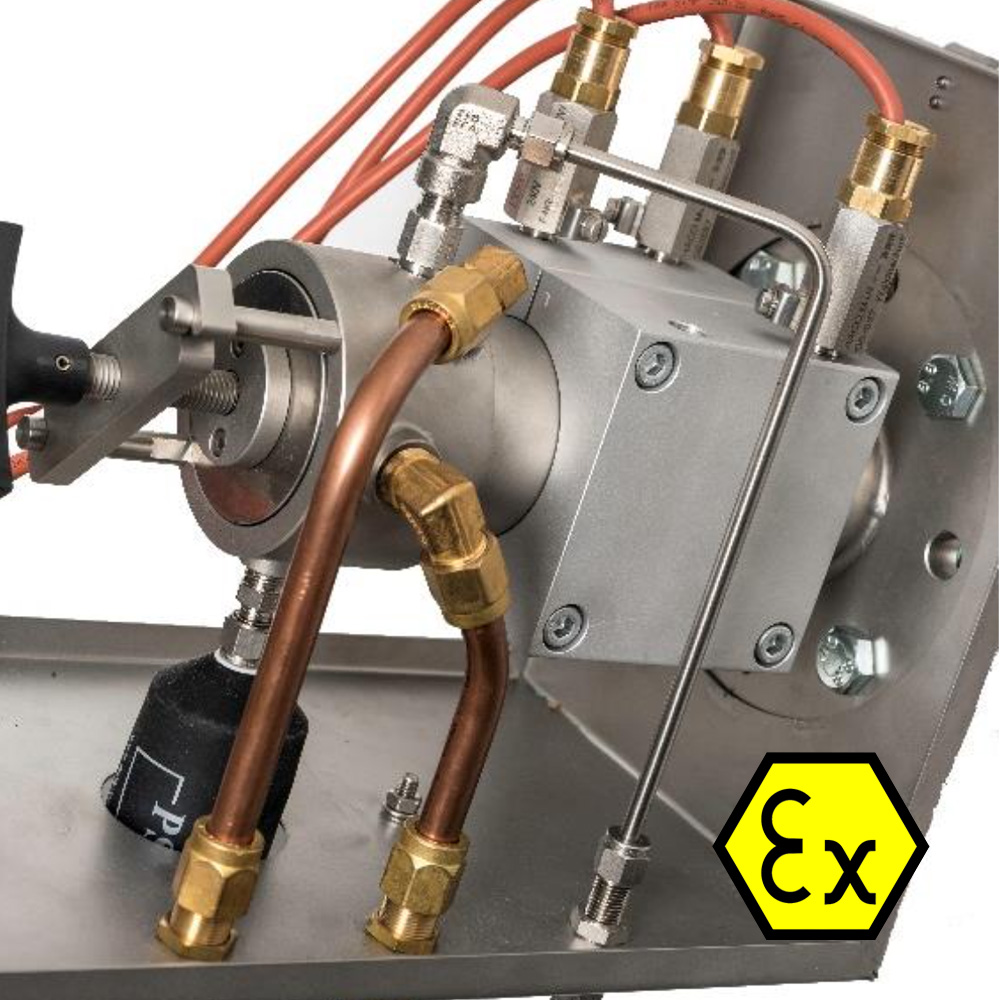

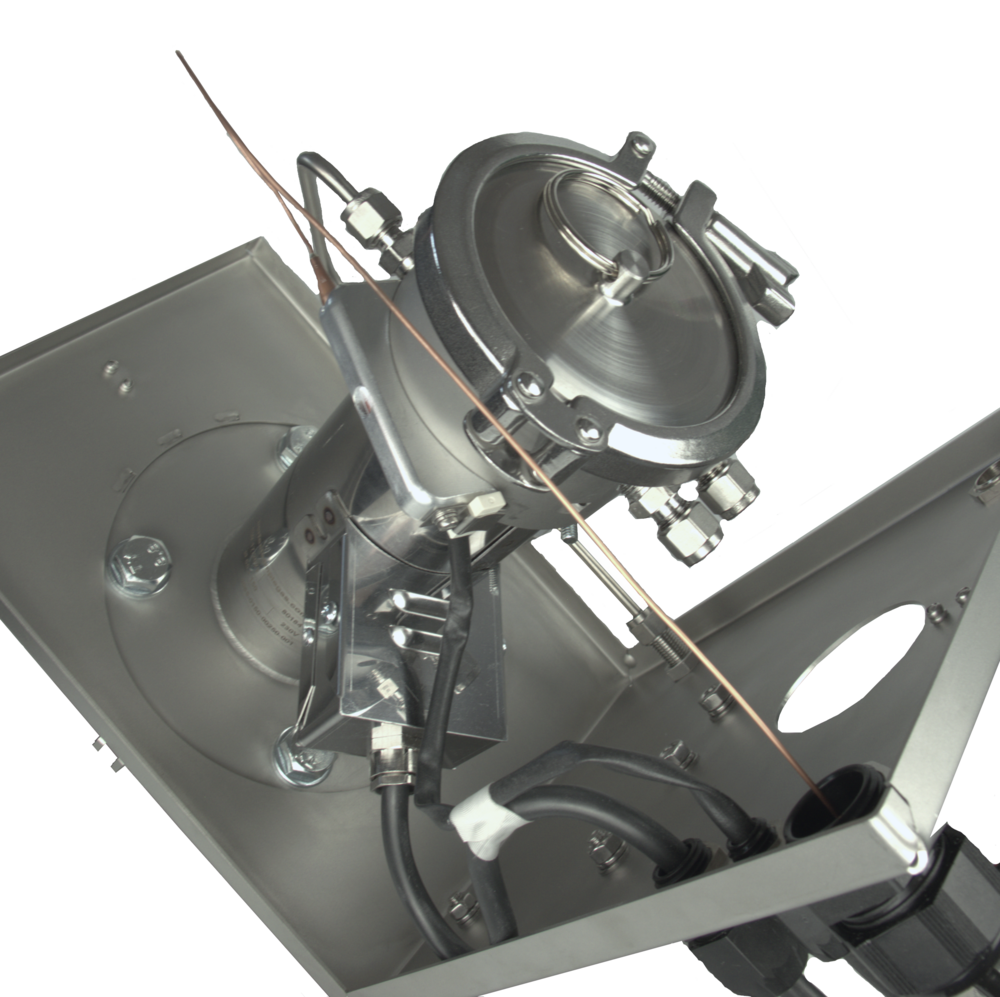

The intelligent design with optimum gas guidance enables the filtration of sample gas at the outer filtration surface of 212cm2 (largest on the market) as well as comfortable and quick filter change without tools and dismounting of the heated sample line. Extremely simple maintenance of the PSG Plus Probe Double Back Purge is enabled due to a sophisticated corkscrew mechanism, which allows opening without effort also at sticking filter housing lid. The holohedral tight high performance ring heater in combination with the tight thick-walled glass fibre insulation jacket ensures a homogeneous heating of the complete PSG Plus Probe Double Back Purge to 180°C. The dual stage back purge with 12x1mm tubing is controlled by optional mounted Coax solenoid valves with 10mm passage.

Functions

Due to the largest filtration surface on the market in combination with the homogeneous heating dust will always be separated reliably in thePSG Plus Probe Double Back Purge without condensation of water vapour and therefore without blocking of the filter. For elevated dust concentrations of up to 280g/m3 the PSG Plus Probe Double Back Purge is equipped with an ultimate effective double stage back purge with 10mm passage which is unique on the market. This way filter as well as filter chamber are purged thoroughly and dust is purged back almost completely into the process. The membrane coated ceramic filter with 0,3μm porosity is supporting additionally the great back purge effectivity.