Properties

- Optimized jet stream heat exchanger principle

- Lowest leaching of measurement gases

- Powerful compressor cooler with 792 KJ / h cooling capacity

- The heat exchanger can be changed without opening the housing

- Gas flow 1 x 150 l / h, 2 x 150 l / h

or 1 x 250 l / h (by connecting the heat exchangers in series) - Long-lasting hot gas bypass system without switching the compressor

- Corrosion-resistant PVDF heat exchangers

- Compact design

- Digital display for temperature and alarms

Potential-free contacts for operational monitoring

Alarm contact

Technical Data + Options

Application

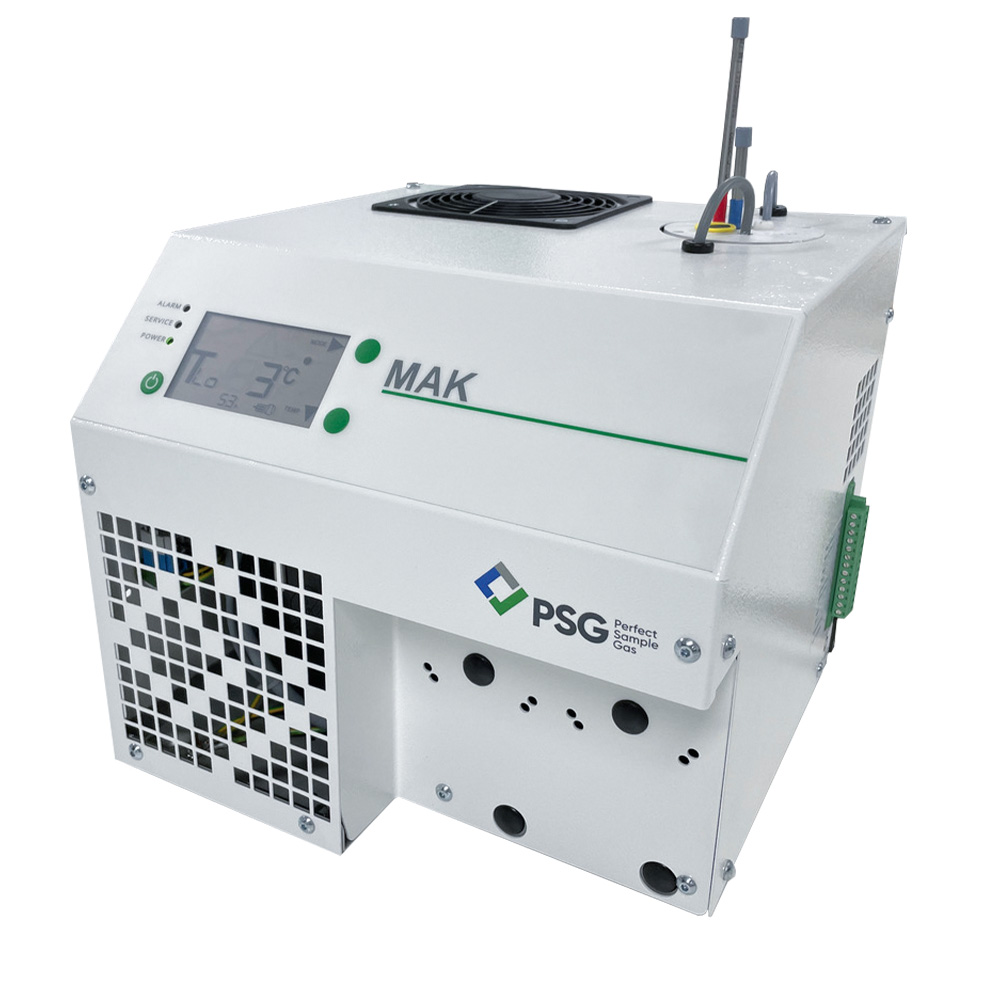

The compact sample gas treatment systems of the MAK BASIC series are used for drying sample gases to exclude condensation in the analyzers. Stable dew points of less than 3°C even with highly fluctuating volume flows with different humidity contents. Volumetric errors or errors caused by H2O cross sensitivity of analysis methods are thus largely eliminated. The MAK BASIC series is also characterized by an optimized JET heat exchanger system in that the leaching of water-soluble gases such as SO2 is reduced to a minimum, which leads to a significant improvement in the analysis results.

Technology

The precise proportional temperature control in combination with the long-lasting hot gas bypass system and the innovative corrosion-resistant heat exchangers achieves low, extremely constant dew points. Load fluctuations and high thermal loads are also reliably compensated. The hydrophobic surface and the very short residence time of the gas in the heat exchanger ensure the lowest possible gas solubility rates.

Functions

An electronic system monitors the cooling temperature and provides a clear display on the unit. A potential-free alarm contact enables remote monitoring of the unit.

You may also be interested in

Exact linear flow rate adjustment with precise fine adjustment valve with high chemical resistance and optional light barrier sensor

Compressor Cooler for Process Measurement (outlet dew point optimized), 1-2 Gas Path, Stainless Steel Heat Exchanger , flow rates up to 500 l/h, Operating pressure up to 100 bar, Additional Temperature Display following SIL

Compressor Cooler for Process Measurement (outlet dew point optimized), 1-4 Gas Path, Heat Exchanger in various Materials, flow rates up to 500 l/h for ATEX EX II 2G Ex px de [ai] IIC T4 Gb

High Performance Compressor Cooler (outlet dew point optimized) with 1-4 Gas Path, Heat Exchanger in various Materials and flow rates up to 500 l/h

High Performance Compressor Cooler (outlet dew point optimized) with 1-4 Gas Path, Heat Exchanger in various Materials and flow rates up to 500 l/h

Compressor Cooler for Process Measurement (outlet dew point optimized), 1-2 Gas Path, Heat Exchanger in various Materials, flow rates up to 350 l/h for Atex-zone 2 (II 3G Ex nA nC T4 Gc)

High Performance Compressor Cooler (outlet dew point optimized) with 1-2 Gas Path, Heat Exchanger in various Materials and flow rates up to 350 l/h

High Performance Compressor Cooler (outlet dew point optimized) with 1-2 Gas Path, Heat Exchanger in various Materials and flow rates up to 250 l/h

Mobile Conditioning System for temporary CEMS, Thermoelectric Cooler Flow Rate up to 250 l/h, integrated Gas Sample Pump and Temoerature controller for PSG Plus Flex Plane integrated in a robust Peli Case

Thermoelectric Cooler for CEMS applications, 1-2 Gas Path, PVDF or SS Jetstream Heat Exchanger , flow rates up to 300 l/h

Compressor Cooler for CEMS (lowest wash out ratio) with JET Stream 1-4 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system

Compressor Cooler for CEMS (wash out optimized) with 1-4 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system, for mobile applications

Thermo Electric Cooler for CEMS (wash out optimized) with 1-2 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system

Compressor Cooler for CEMS (wash out optimized) with 1-4 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system

Condensate Separation for Pre-cooling to ambient temperature with high water vapour and ambient temperatures

Self-suctioning Peristaltic Pump SR 25 with Synchronous motor and high chemical resistance

Electronic Control for alerting liquid sensor and Potential-free switch-contact for liquid sensor alerting

Corrosion resistant PTFE diaphragm sample gas pump (Integration into the MAK product line possible)

Depth Filter for the protection of the Analyzer against fine dust in PTFE and Glass Fibber versions

Safe detection of condensate as protection for the Analyzer with long lasting platinum electrodes