Properties

Reliable protection of the analyzer against fine dust

Safe separation of dust particles up to 0,1µm

Durable corrosion resistant inert filter element

Quick and easy change of filter element

Two filter sizes available

Easy mounting and integration

High chemical resistance

Low dead volume for fast response time

Optical control of degree of contamination

Front panel and wall mounting (with optional mounting bracket)

Technical Data and Options

Application

The depth filters series TF are used for continuous extractive gas analytics. They are usually integrated downstream the sample gas cooler and serve for fine dust separation from the sample gas to protect the analyzer from damage.

Technology

The depth filters series TFare designed particularly corrosion resistant and easy to maintain. Filter cartridge in PTFE or glass fiber, filter body and holder are made of PVDF, lid is made of glass and sealing is made of FKM. The PTFE filter element has a porosity of 0.1µm a large filter surface of 67cm2 resp. 86cm2 and an especially low pressure drop of only a few mbar. Regarding design special attention was also paid to an extra low dead volume for fast response time. Due to the G1/8” f-thread the sample gas connections can be determined variably by means of an appropriate screw fitting.

Functions

Due to the PTFE depth filters series TFfine dust particles up to a grain size of 0.1µm are separated reliably. The glass lid allows quick and easy to assess the degree of contamination of the filter element. The easy-to-loosen PVDF knurled nut enables opening with quick and easy change of the filter element.

You may also be interested in

Exact linear flow rate adjustment with precise fine adjustment valve with high chemical resistance and optional light barrier sensor

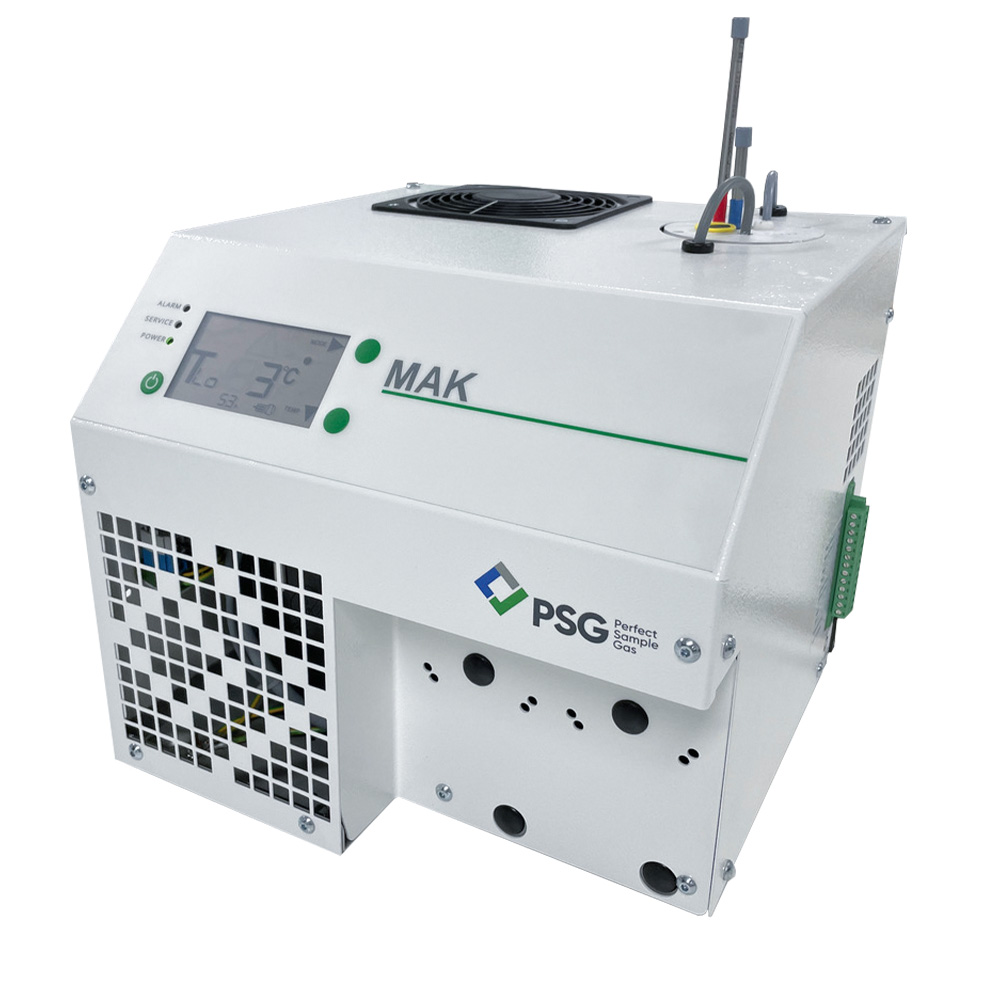

Compressor Cooler for Process Measurement (outlet dew point optimized), 1-2 Gas Path, Stainless Steel Heat Exchanger , flow rates up to 500 l/h, Operating pressure up to 100 bar, Additional Temperature Display following SIL

Compressor Cooler for Process Measurement (outlet dew point optimized), 1-4 Gas Path, Heat Exchanger in various Materials, flow rates up to 500 l/h for ATEX EX II 2G Ex px de [ai] IIC T4 Gb

High Performance Compressor Cooler (outlet dew point optimized) with 1-4 Gas Path, Heat Exchanger in various Materials and flow rates up to 500 l/h

High Performance Compressor Cooler (outlet dew point optimized) with 1-4 Gas Path, Heat Exchanger in various Materials and flow rates up to 500 l/h

Compressor Cooler for Process Measurement (outlet dew point optimized), 1-2 Gas Path, Heat Exchanger in various Materials, flow rates up to 350 l/h for Atex-zone 2 (II 3G Ex nA nC T4 Gc)

High Performance Compressor Cooler (outlet dew point optimized) with 1-2 Gas Path, Heat Exchanger in various Materials and flow rates up to 350 l/h

High Performance Compressor Cooler (outlet dew point optimized) with 1-2 Gas Path, Heat Exchanger in various Materials and flow rates up to 250 l/h

Mobile Conditioning System for temporary CEMS, Thermoelectric Cooler Flow Rate up to 250 l/h, integrated Gas Sample Pump and Temoerature controller for PSG Plus Flex Plane integrated in a robust Peli Case

Thermoelectric Cooler for CEMS applications, 1-2 Gas Path, PVDF or SS Jetstream Heat Exchanger , flow rates up to 300 l/h

Compressor Cooler for CEMS (lowest wash out ratio) with JET Stream 1-4 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system

Compressor Cooler for CEMS (wash out optimized) with 1-4 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system, for mobile applications

Thermo Electric Cooler for CEMS (wash out optimized) with 1-2 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system

Compressor Cooler for CEMS (wash out optimized) with 1-4 Gas Path, Flow Rate up to 150 l/h and update options to full conditioing system

Compressor Cooler for CEMS applications, 1-2 Gas Path, PVDF Jetstream Heat Exchanger , flow rates up to 250 l/h

Condensate Separation for Pre-cooling to ambient temperature with high water vapour and ambient temperatures

Self-suctioning Peristaltic Pump SR 25 with Synchronous motor and high chemical resistance

Electronic Control for alerting liquid sensor and Potential-free switch-contact for liquid sensor alerting

Corrosion resistant PTFE diaphragm sample gas pump (Integration into the MAK product line possible)

Safe detection of condensate as protection for the Analyzer with long lasting platinum electrodes