Requirements for ATEX Areas

The topic of safety in industrial plants is one of the core issues in the global process industry.

Especially in chemical and petrochemical plants, individual components of sample preparation or even complete analysis systems are often operated within an explosion-proof zone.

The majority of these applications are found in the area of process control, process optimization and process safety.

Power plants and petrochemistry

But also in industrial power plants in industrial parks, or plants for the incineration of industrial residues and waste, the use of ATEX solutions is becoming increasingly common.

Particularly with regard to the corrosive and explosive components found in the chemical and petrochemical industries, high demands are sometimes placed on the use of ATEX components and systems.

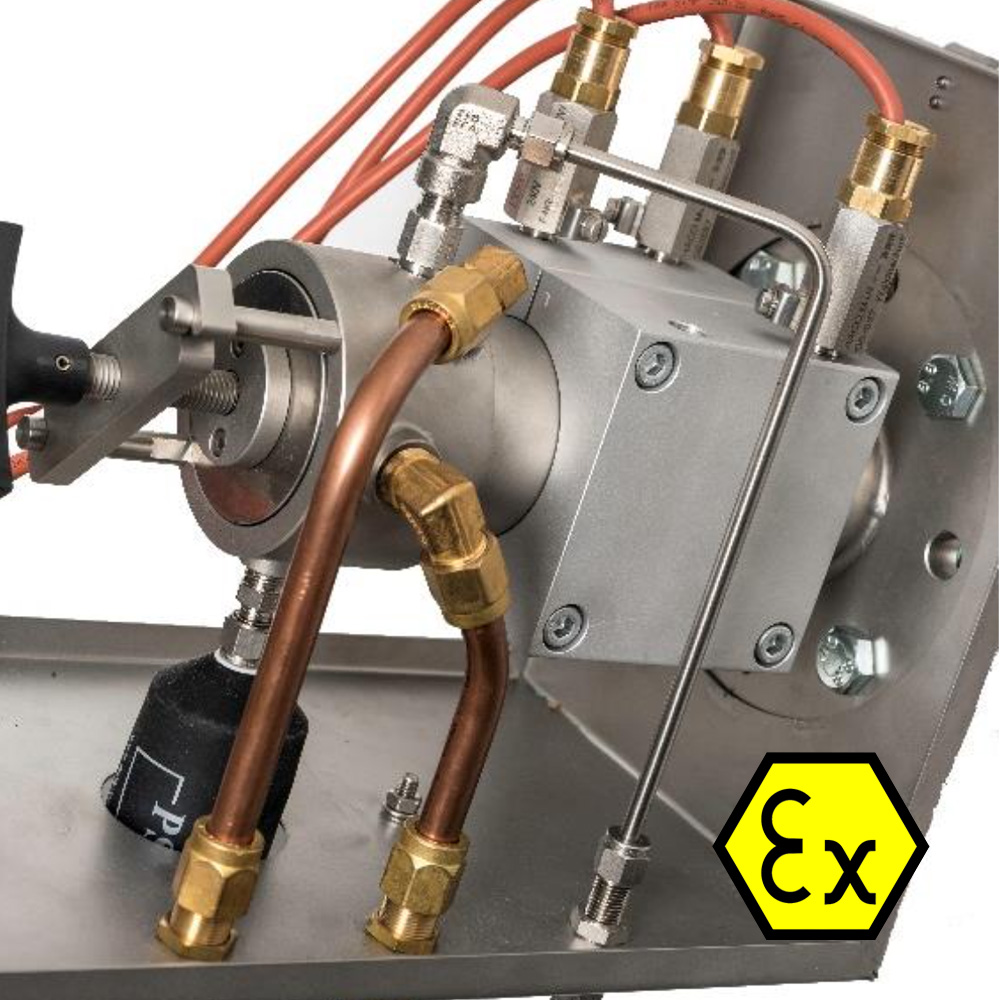

PSG Process Probe for ATEX Areas up to 180°C

In addition to the special advantage that the PSG Process probes can do without an additional controller and limiting unit due to self-limiting heating cartridges (90°C, 150°C, 180°C), an additional high protection class up to IP 65 is achieved via a conductive GRP protective box.

Even for systems that have extremely high requirements for a stable sampling temperature of 180°C due to acid dew points, the required temperature can be achieved for zone II 2G Ex d IIC T3 via self-limiting heating, even at very low ambient temperatures (down to -40°C).

Special Filter Design for low Maintenance

Due to the surface design of the filter, very long service lives are achieved both at high and low dust contents, which are common in the process industry. It is precisely this property that enables operators of potentially explosive plants to reduce the working and maintenance times in their ATEX plants to a minimum.

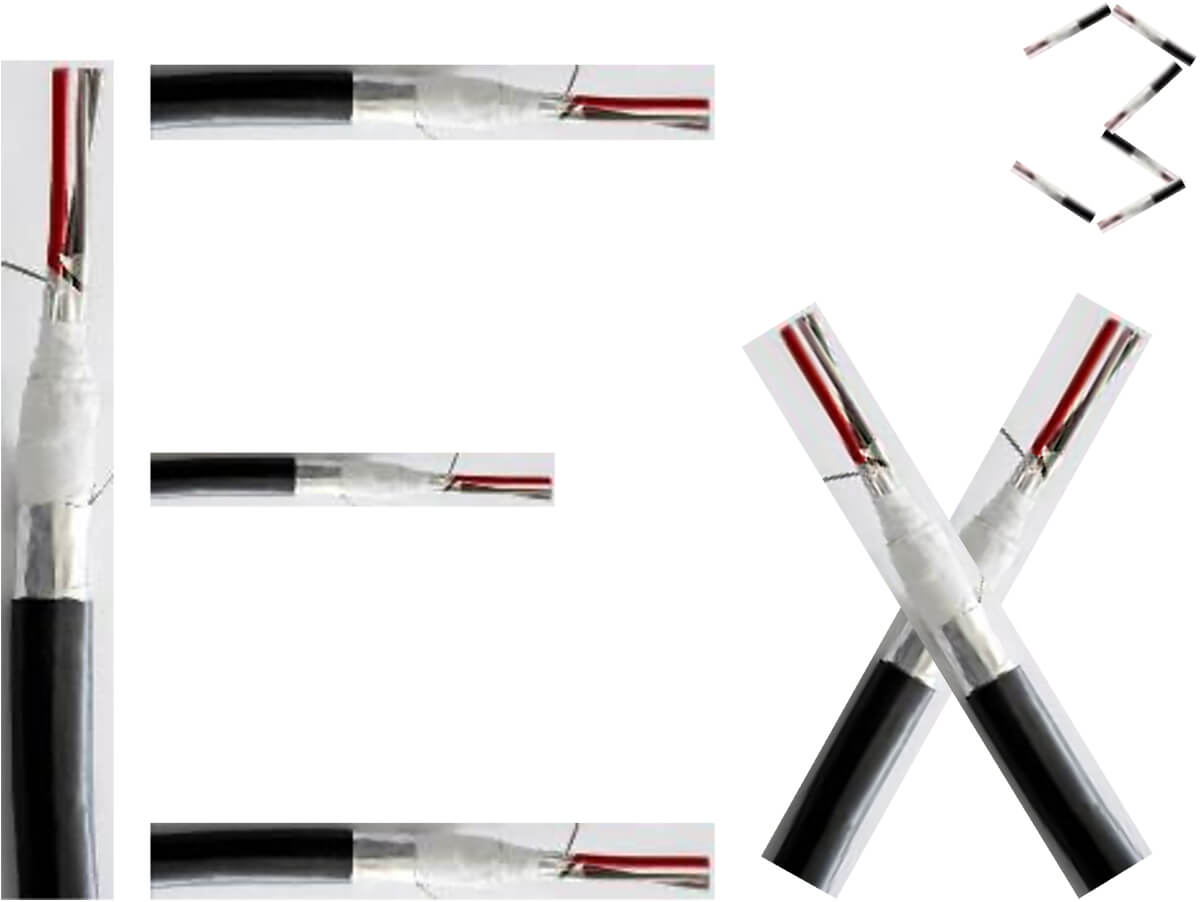

Cut-to-length and fully certified PSG Process ATEX

Even heated sample lines, which usually seem trivial, have to meet a wide range of requirements in the ATEX area. Requirements are, for example, the assembly, the laying, the supply, as well as the electrostatic properties of the lines.

With the shortenable PSG Process ATEX cables, holding temperatures of up to 180 °C can be achieved and adjusted to the correct length in the system using the convenient cut-to-length technology.

Conductive Surface of the Jacket Material

This feature reduces unnecessary installation work, optimizes the use of resources and also saves energy, since the heating tape, thanks to efficient insulation technology with a maximum power output of 60 W / m, allows energy savings of more than 50% compared to conventional solutions.

Thanks to the patented technology of a fully conductive outer jacket (antistatic), not only the heating tape, but the complete assembly is fully certified.

PSG Process Cooler for ATEX Zone 1 and 2

Applications and installation locations for sample gas coolers are often found in analyzer systems in explosion-free areas (safe area).

However, especially when it comes to critical and important measurements, applications for inerting or the measurement of flammable gases, coolers for use in the ATEX zone are increasingly used.

Integrated SIL Temperature Measurement

With the new MAK Process, the requirements of the process industry are taken into account in one device. High flow rates to reduce T90 times, an integrated SIL temperature measurement, stainless steel piped gas paths and a stainless steel heat exchanger ensure all-round safe use of the sample gas cooler.