Properties

Application

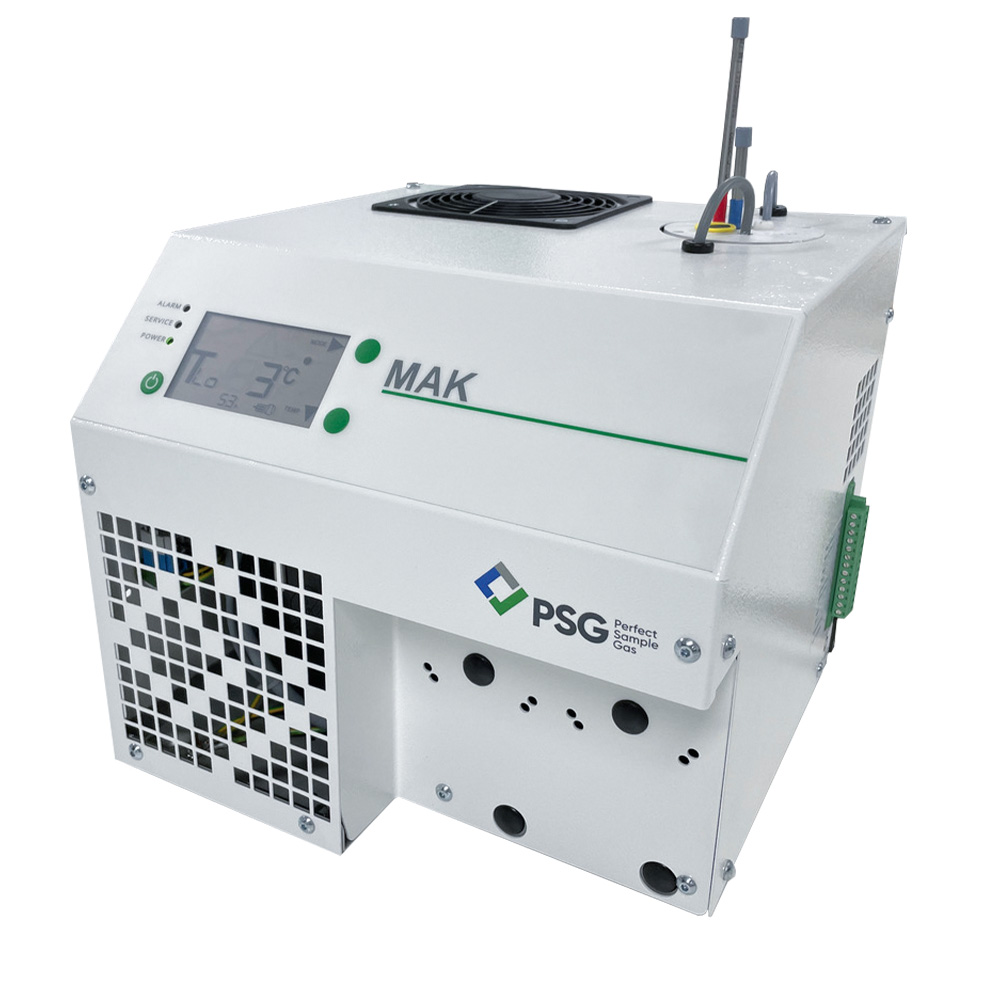

The compact sample gas treatment systems of the MAK 20 series are used for drying sample gases to exclude condensation in the analyzers. Stable dew points of less than 3°C can be guaranteed even with highly fluctuating volume flows with different humidity contents. Volumetric errors or errors caused by H2O cross sensitivity of analysis methods are thus largely eliminated. The MAK 20 series is also characterized by an optimized JET heat exchanger system in that the leaching of water-soluble gases such as SO2 is reduced to a minimum, which leads to a significant improvement in the analysis results.

Technology

The precise proportional temperature control in combination with the long-lasting hot gas bypass system and the innovative corrosion-resistant heat exchangers achieves low, extremely constant dew points. Load fluctuations and high thermal loads are also reliably compensated. The hydrophobic surface and the very short residence time of the gas in the heat exchanger ensure the lowest possible gas solubility rates.

Functions

An electronic system monitors dew point and cooling air temperature. Potential-free alarm contacts enable remote monitoring of the device. The operating parameters are stored in a logbook for diagnostics. An operating hour counter monitors the service intervals.